Complete Vertical Manufacturing Company

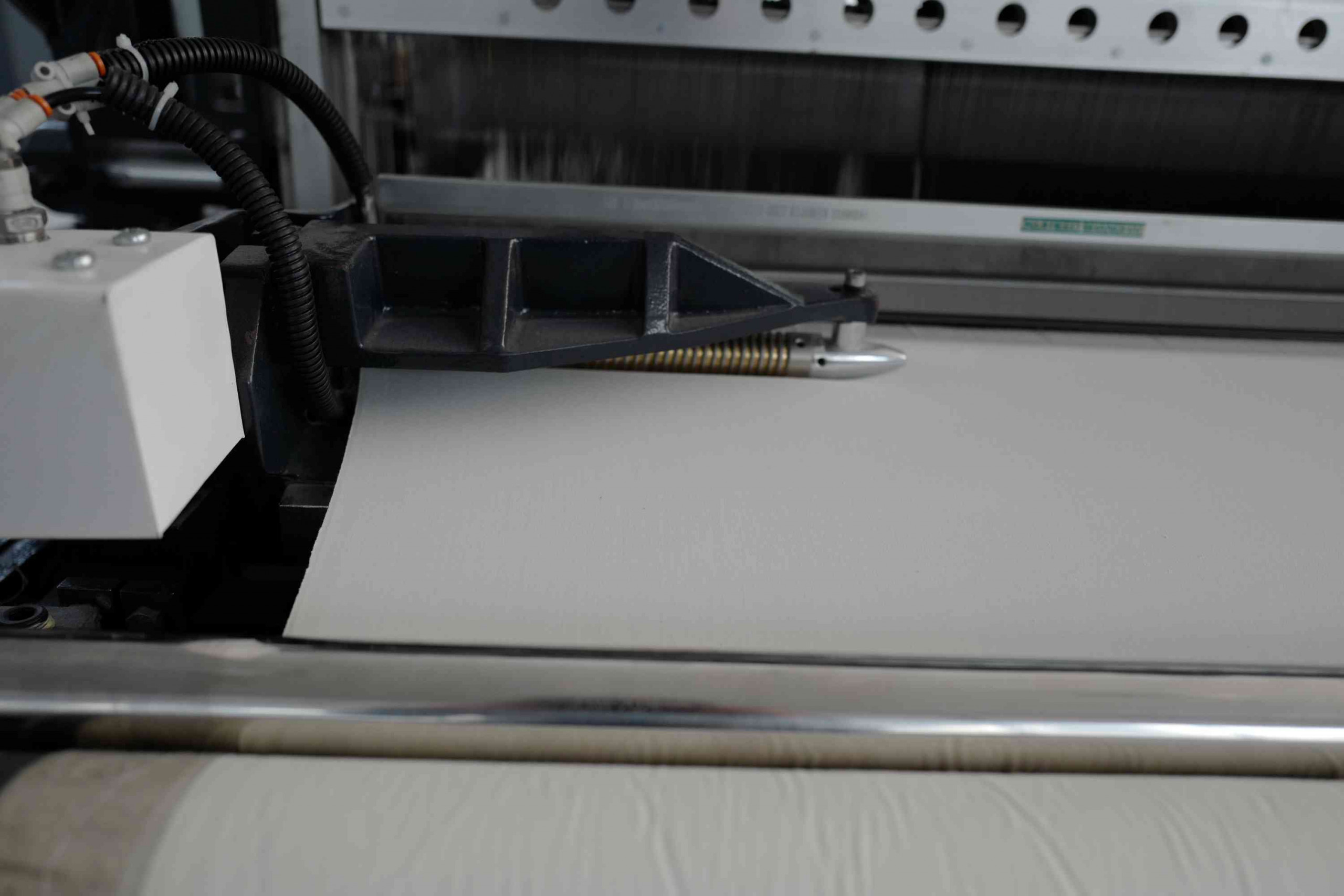

Coral Weaver takes pride in being an innovation driven and technology focused company. We are

in a

constant mode to upgrade our infrastructure, and adopt newer solutions with an aim to

continuously improve, promote efficiency, and uplift quality levels. Our manufacturing

excellence has been recognized and awarded by renowned institutions like Quality Circle

Forum of India, and ABK-AOTS DOSOKAI for practicing best 5s and TPM Standards.

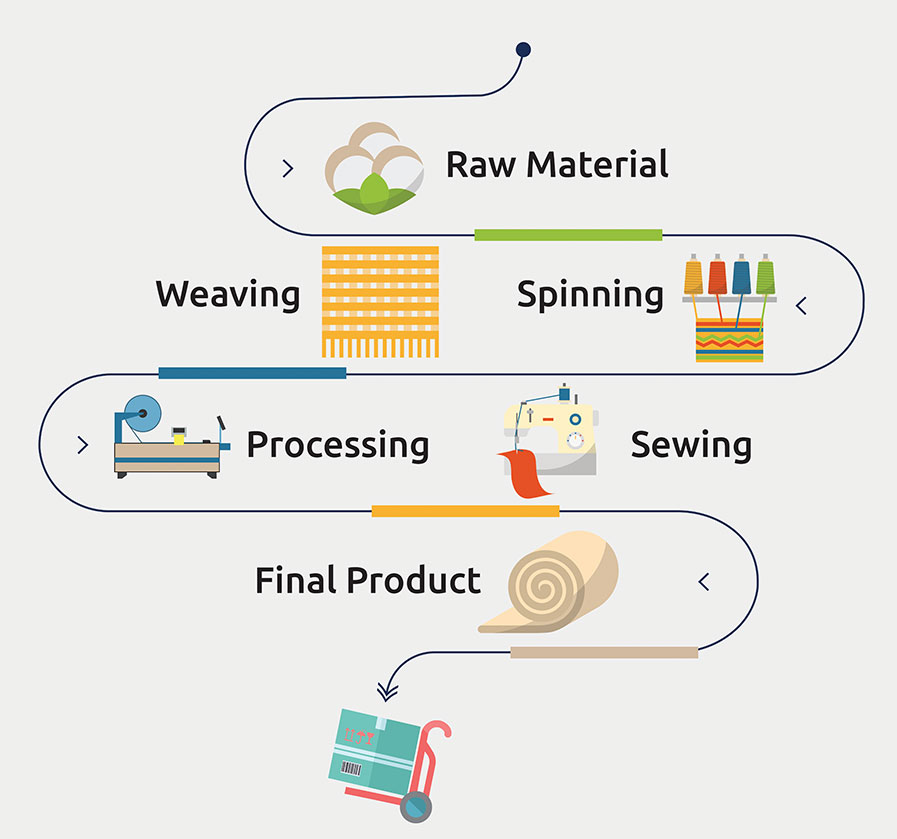

Right from - Raw Material, to spinning, weaving, processing, sewing to Made ups.

The backbone of our production infrastructure is the vertically integrated model which gives

us full control over the entire lifecycle of the manufacturing process. This infuses a

significant amount of efficiency into the supply chain which delivers considerable value to

all downstream stakeholders along the chain up to the final consumers. The set-up also

provides traceability and improved transparency which is extremely critical in tracking back

inputs and processing to substantiate Sustainability and increased ability to achieve value

chains all across.

Our world-class, state-of-the-art integrated production unit comprises of

- Spinning

- Weaving

- Made Ups